Overview:The HZG rotary drum dryer is a cylinder with a slightly inclined main body and adjustable speed within a certain range. The wet material is fed into the cylinder by the feeder,

Consultingworking principle

After the wet material is input from one end of the dryer, the material is evenly distributed and dispersed in the dryer under the turning of the evenly distributed plate copying device in the inner cylinder, and fully contacted with the co-current (counter-current) hot air, which speeds up the drying and heat transfer. Pass to the driving force. During the drying process, the material can be moved to another section of the dryer to discharge the finished product under the action of the inclined plate and the hot air flow.

Adapt to materials

◎In the chemical, mining, metallurgical and other industries, large particles and heavy-weight materials are dried, such as mines, blast furnace slag, coal, metal powder, phosphate fertilizer, and ammonium sulfate.

◎Dry powder and granular materials with special requirements, such as HP foaming agent, distiller's grains, light calcium carbonate, activated clay, magnetic powder, graphite, and medicine residue.

◎Materials requiring low-temperature drying and continuous drying in large quantities.

Performance characteristics

◎The drum dryer has a high degree of mechanization and a large production capacity.

◎The resistance of the fluid through the cylinder is small, and the function consumption is low.

◎Strong adaptability to material characteristics.

◎The operation is stable, the operation cost is low, and the product drying uniformity is good.

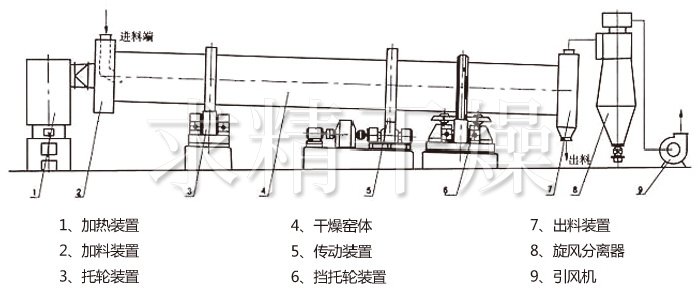

Schematic

Technical specifications

| model | Direct heating downstream | Direct heating downstream | Direct heating countercurrent | Direct heating countercurrent | Compound heating | Compound heating |

| Material type | 矿石 | HP blowing agent | Blast furnace slag | Ammonium Sulfate | Phosphate fertilizer | coal |

| Processing capacity(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Water content(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final water content(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| The average particle size(mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Material accumulation weight(kg/m3) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Hot air volume(kg/h) | 3900 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet gas temperature(oC) | 600 | 165 | 500 | 180 | 650 | 570 |

| Material outlet temperature(oC) | 42 | 100 | 70 | 80 | 75 | |

| way to heat up | gas | Steam electric heating | heavy oil | Coal-fired hot blast stove | heavy oil | heavy oil |

| Loading factor | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating speed(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Inclination | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Number of copy boards | 12 | 24 | 12 | 22 |

Outside the inner cylinder8 Outside the inner cylinder16 |

6 12 |

| Dryer diameter(m) | 2.0 | 1.5 | 2 | 2.3 |

Outer tube2 Inner tube0.84 |

Outer tube2.4 Inner tube0.95 |

| Length of dryer(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…