Overview:The fluidized bed dryer enters the machine from the feed inlet. Under the action of vibration, the materials are thrown along the horizontal fluidized bed and move forward continuously.

Consulting

working principle

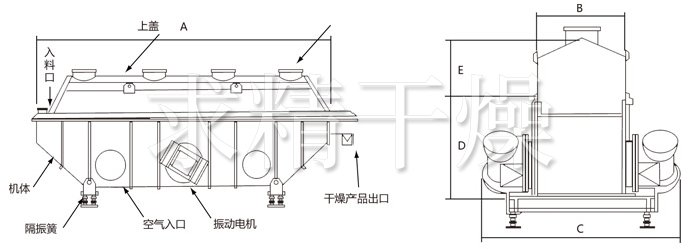

The material enters the machine from the feed inlet. Under the action of vibration, the material is thrown along the horizontal fluidized bed and moves forward continuously. After the hot air passes through the fluidized bed and exchanges heat with the wet material, the wet air passes through the cyclone separator to remove dust. Exhaust by exhaust air 1:3. Dry materials are discharged from the discharge inlet.

Schematic

Adapt to materials

Suitable for drying and cooling of powdery and granular materials in chemical, pharmaceutical, food, dehydrated vegetables, grain, minerals and other industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, dill, silk, soybean meal, distiller's grains, seeds, slag, sugar, etc.

Performance characteristics

◎The vibration source is driven by a vibrating motor, with stable operation, convenient maintenance, low noise and long life.

◎The fluidization is well-proportioned, there is no dead space and blow-through phenomenon, and uniform drying and cooling products can be obtained.

◎Good adjustability and wide application area. The thickness of the material layer, the moving speed in the machine and the change of the full amplitude can be steplessly adjusted.

◎Small damage to the surface of the material. It can be used for drying fragile materials, and the work effect will not be affected even when the material particles are irregular.

◎Using a fully enclosed structure. Effectively prevent cross-infection between materials and air, and the working environment is clean.

◎High mechanical and thermal efficiency, good energy-saving effect, 30-60% energy saving than ordinary drying devices.

Technical specifications

| Size/Model | A | B | C | D | E | F | weight(kg) |

| GZQ3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| GZQ4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| GZQ6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| GZQ6×0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| GZQ6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2840 |

| GZQ6×0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| GZQ7.5×0.60 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| GZQ7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| GZQ7.5×0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| GZQ7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| model |

Fluidized bed area (M2) |

Inlet air temperature (oC) |

Outlet temperature (oC) |

Water evaporation capacity (kg) |

Vibration motor | |

| model | power Kw | |||||

| GZQ3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| GZQ4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| GZQ6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| GZQ6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| GZQ6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| GZQ6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| GZQ7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| GZQ7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

★The above evaporation capacity is the upper limit of evaporation capacity.

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…