Overview:The YPG series pressure spray (cooling) dryer adopts a pressure atomizer to atomize the solution or slurry material into fine droplets with the pressure of the diaphragm pump, so that the surface area is significantly increased,

Consulting

product description

This unit is a device that can complete drying and granulation at the same time. According to process requirements, the pressure, flow rate and size of nozzle holes of the feed liquid pump can be adjusted to obtain the required spherical particles in a certain size ratio.

working principle

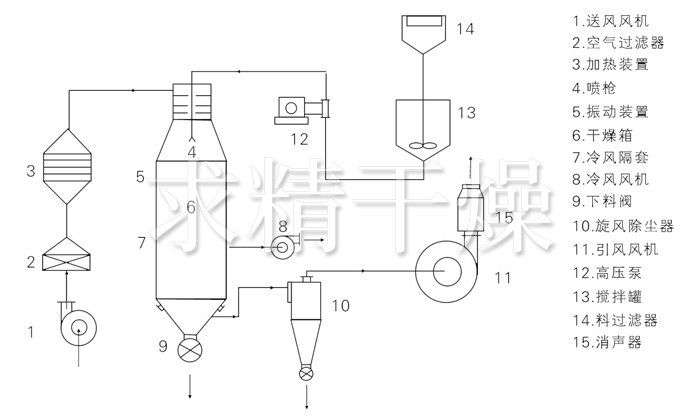

The working process of this unit is that the material liquid is input through the diaphragm pump under high pressure, spraying mist-like droplets, and then falling in parallel with the hot air. Most of the powder particles are collected by the discharge port at the bottom of the tower, and the waste gas and its tiny powder are separated by the cyclone separator. , The exhaust gas is discharged by the exhaust fan, and the powder is collected by the pollinator at the lower end of the cyclone separator. The outlet of the fan can also be equipped with a secondary dust removal device, and the recovery rate is above 96-98%.

Schematic

Performance characteristics

◎The drying speed is fast, and the surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95%-98% of the water can be evaporated in an instant, and the drying time only needs ten to tens of seconds, especially suitable For the drying of heat-sensitive materials.

◎All products are spherical particles with uniform particle size, good fluidity, good solubility, high product purity and good quality.

◎Wide range of application, according to the characteristics of the material, it can be dried with hot air or granulated with cold air, which has strong adaptability to the material.

◎Simple and stable operation, convenient control, easy to realize automatic operation.

Adapt to materials

Spray dried granules:

◎C

hemical industry: There are catalysts, resins, synthetic detergents, oils, ammonium sulfate, dyes, dye intermediates, white carbon black, graphite, ammonium phosphate, etc.

◎Food: amino acids and analogues, seasonings, protein, starch, dairy products, coffee extracts, fish meal, meat essence, etc.

◎Pharmaceuticals: Chinese patent medicines, pesticides, antibiotics, pharmaceutical granules, etc.

◎Ceramics: Magnesium oxide, porcelain clay, various metal oxides, dolomite, etc.

◎Spraying granulation: all kinds of fertilizer, alumina, ceramic powder, pharmaceutical, heavy metal superhard steel, chemical fertilizer, granular washing powder, Chinese patent medicine.

◎Spray cooling granulation: amino fatty acid, paraffin wax, glycerate, tallow, etc. It is often used in spray crystallization, spray concentration, and spray reaction.

Technical specifications

| model | unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation | kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Dimensions(Ф×H) | mm | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×1880 | 4600×22500 |

| High pressure pump pressure | mPa | 2~10 | ||||||

| power | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Inlet air temperature | oC | 140~350 | ||||||

| Product moisture content | % | <5(Reachable0.5) | ||||||

| Material recovery | % | >97 | ||||||

| Electric heating | KW | 75 | 120 | 150 | When the temperature is lower than 200, according to actual technology | |||

| Electricity plus steam | Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| Hot stove | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

★The above evaporation capacity is the upper limit of evaporation capacity.

Drying equipment is very widely used in industrial testing, and it is necessary to use drying equipment in many fields. Similarly, drying equ…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal as a primary energy source releases a large …

ZPG special spray dryer for traditional Chinese medicine extract is a special spray dryer.

Although belt dryers are currently more energy-efficient and energy-saving dryers, failures may occur in actual operation. What we do is to f…

Belt dryers have a wide range of applications, and they are currently used in pharmaceutical, food, biological, chemical and other fields. Ho…

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…